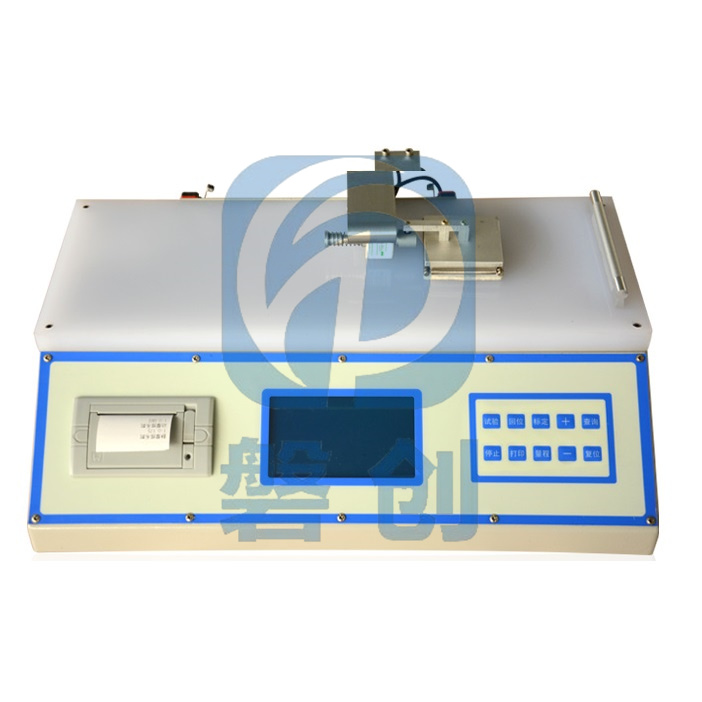

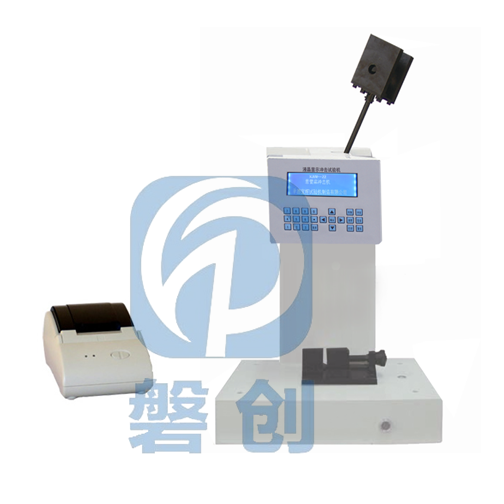

Main specification

1. Extrusion part

Discharge outlet diameter: Φ2.095±0.005mm

Length of outlet: 8.000±0.025mm

Drum diameter: Φ9.550±0.025mm

Loading barrel length: 152± 0.1mm

Piston rod head diameter: 9.475±0.015mm

Piston rod head length: 6.350±0.100mm

2. Standard test load (8 levels)

Level 1: 0.325kg = (piston rod + weight tray + heat insulation sleeve + No.1 weight ) = 3.187N

Level 2: 1.200 kg = (0.325 + No. 2 0.875 weight) = 11.77N

Level 3:2.160kg= (0.325+No.3 1.835 weight) =21.18N

Level 4:3.800kg= (0.325+No.4 3.475 weight) =37.26N

Level 5:5.000kg= (0.325+ No.5 4.675 weight) =49.03N

Level 6:10.000kg= (0.325+ No.5 4.675 weight + No.6 5.000 weight) =98.07N

Level 7:12.500kg= (0.325+ No.5 4.675 weight + No.6 5.000 weight + No .7 2.500 weight)=122.58N

Level 8:21.600kg= (0.325+ No.5 4.675 weight + No.6 5.000 weight + No .7 2.500 weight + No .8 2.915 weight) =211.82N

3. Temperature range: room temperature—400℃

4. Constant temperature accuracy: ±0.1℃

5. Display resolution: 0.1℃

6. Temperature recovery time: less than 4 minutes

7. Cutting times: 1-99 times

8. Cutting time interval: 10-600 seconds

9. Constant Temperature Time: It can work for tens of thousands of hours continuously.

10. Supply voltage: AC220V±10% 50HZ

11. Outward Size: (W * T * H) 250×350×510mm

中文

中文

English

English